At A Glance | |

Operator | Agata Mining Ventures Inc. (AMVI) |

Ownership of AMVI | TVI Resource Development Philippines Inc. – 60% Minimax Mineral Exploration Corporation – 25% MRL Nickel Philippines Inc. – 15% |

Location | Jabonga, Santiago and Tubay Municipalities, Agusan del Norte |

Business activities | Prospective limestone direct shipping ore (DSO) operations |

Resources | 35.6 million tonnes at 54.5% Calcium Oxide |

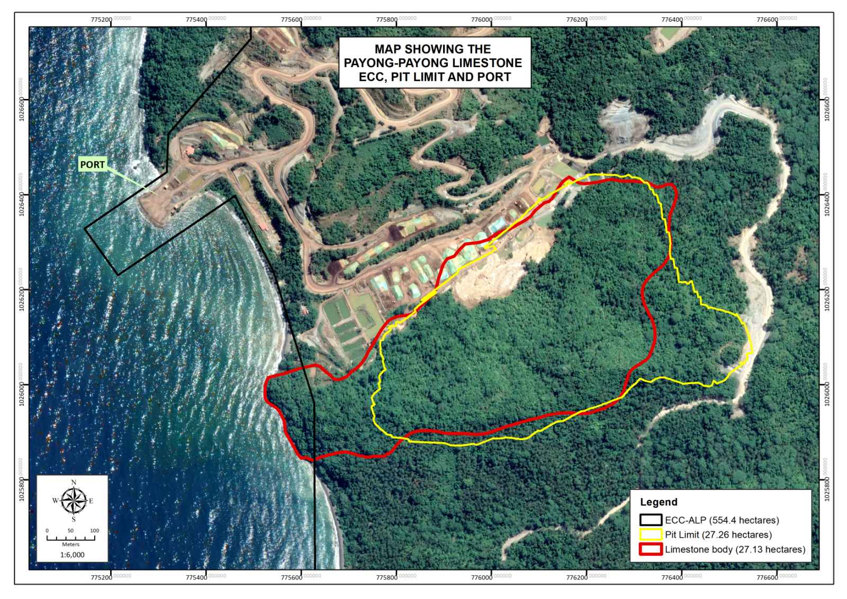

Logistics | Mining areas are within one (1) kilometer from the port |

The Agata Limestone Project (ALP) is held by Agata Mining Ventures Inc. (or “Agata” in which TVIRD has a 60% interest). The project is covered by Mineral Production Sharing Agreement (MPSA) No. 134-99-XIII which was granted to Minimax Mineral Exploration Corp. (Minimax).

The approved MPSA appointed MRL Nickel Philippines Inc. (MRL) as Operator to conduct mineral exploration within the 4,995-ha contract area, pursuant to the June 27, 1997 Deed of Assignment .

Parties Minimax, MRL and TVIRD entered into a Joint Venture Agreement in September 25, 2012 for the development of the Agata Property. The JV Parties formed Joint Venture Companies to develop and operate the Agata tenement, among which the appointed mining company is Agata Mining Ventures Inc.

The ALP site is located in a 4,995-hectare MPSA area in the adjacent municipalities of Tubay, Jabonga and Santiago, all in Agusan del Norte province. It is accessible by land (approximately 1.5-hours driving time) from the provincial capital of Butuan.

The project mine site is located at a very short trucking distance from Agata’s private port, which is strategically located within proximity to main markets in Asia and bears the opportunity for shipping all year round.

The whole MPSA is largely underlain by the Cretaceous basement rocks of the Humandum Serpentinite and the Concepcion Greenschist. The former, believed to be a dismembered part of the Dinagat Ophiolite, is found in thrust contact with the latter and other metamorphic rocks. Humandum Serpentinite rocks include peridotite, pyroxenite, dunite, serpentinite and minor distribution of gabbro. On the other hand, Concepcion Greenschist is an interbedded metasedimentary and metavolcanic sequence. Within the metasedimentary succession are calcareous layers where the recrystallized limestone deposit of Payong -payong is located.

The Payong-payong limestone forms a sub-horizontal continuous bed, striking NE and dipping gently at NW direction. The limestone exhibits characteristics which suggest that it has been subjected to low grade metamorphism. The mapped units are massive and recrystallized textures are apparent.

The mineralized units comprise intercalating layers of metamorphic rocks and lenses of recrystallized limestone with assay results ranging from 80% to 100% CaCO3. The limestone is relatively clean with minimal to negligible impurities of iron and other base metals. A high -purity limestone was revealed during drilling of the deposit exhibiting about 40 to 50 m thick, white to gray, metamorphosed limestone.

The exploration for limestone in Agata was first initiated by MRL in 2011, when the company was scouting for raw materials to be utilized in the proposed nickel processing plant. Gridline-based mapping has been undertaken which was then followed by drilling of five (5) drillholes. Given the encouraging results of the initial drilling, Agata decided to pursue the Project by drilling more holes within the 32-ha perimeter of the Payong-payong area. The Company drilled a total of 17 drill holes at 100-m spacing. Results had confirmed the presence of a high-purity recrystallized limestone deposit covering an area of 600 m by 650 m.

The exploration drilling program for the Project involves Quality Assurance and Quality Control (QA/QC) protocols to monitor laboratory performance in terms of analytical accuracy, precision and bias. Core samples were analyzed at the Agata Mine Laboratory using XRF method. Each batch of sample dispatch includes coarse blanks and coarse duplicate inserted randomly.

A preliminary economic assessment indicates a capital requirement of an estimated USD 6-8 million for a two (2) million ton per annum mining and processing facility for direct shipping of limestone products to the steel and power industries. Due to the project’s proximity to the causeway where materials will be shipped, potential operations will benefit from having low transport and handling costs.

A limestone quarrying and processing plant will be established to economically develop, extract and utilize the limestone deposit. Mining will be simultaneously operated with the processing. Conventional method of quarrying will be carried out to deliver limestone for further crushing and screening. The processing method to be employed for producing limestone lumps is simply by crushing and screening. A crushing and screening module having a capacity of 700 t/h will be installed to make an annual crushed limestone production of about two (2) million tons.

From the crushing plant, crushed limestone will be transported to the screening facility located at the existing nickel laterite pier yards. The material will pass through primary and secondary vibrating screens and will be segregated into different stockpiles. Products will be transported to the port via a 1.5 km covered conveyor belt or directly loaded to feeder vessels using hauling dump trucks then transferred to cargo ships using their crane grabs.

There are four kinds of products to be produced by the Project: (1) crushed medium limestone lumps, (2) crushed medium-small limestone lumps, (3) crushed small limestone lumps and (4) limestone fines.

The estimated Mineral Resource for Agata Limestone Project using a cut-off grade of 45% CaO stands at around 35.6 million tons at 54.5% CaO (97% CaCO3).

The Mineral Resource estimate for the Project has been classified as Indicated Resource given that the drill spacing is at 100 m by 100 m. No Measured Resources have been defined.

The Ore Reserve is classified as Probable Ore Reserve. It is estimated at 30.08 million tons at 54.32% CaO (97% CaCO3) using a cut off grade of 90% CaCO3.The categorization indicates the bulk of the reserve falling under the high-grade classification.

A Mine Plan and Design was already done for a 2 million metric tons per year production. This would mean a Life of Mine (LOM) of fifteen (15) years. The proximity of the loading port (see map) from the limestone deposit and crushing plant would mean low hauling costs and year-round operations. The port loading stations are located some 800 meters from the pier head and can accommodate vessels as large as 100,000 tons capacities.

r5hd74

15z59f

xqbp8z

qriu19

wu5a71

u9ly9b

ah53wf

bqfimo

wpnl2q

jho9w2

s6yc6x

4w1gsp

4mvarb

I am always looking online for tips that can aid me. Thank you!

y76yir

In 1992 won his fifth Iceland’s Strongest Man title in addition to Finland’s Strongest Man. Both in 1991 and 1992 he missed the World’s Strongest Man due to recurring accidents.

In the video, Bjornsson finishes his boxing session with a spin on an assault bike, the place he does 30 secs gradual, 20 secs at

a average intensity and 10 secs “tremendous quick”.

He does this five occasions, rests for 3 minutes and then does

the identical factor another three to 6 instances. Björnsson – who is greatest known for his function as The Mountain in Sport of Thrones – took to Instagram to reveal his weight loss, which has

seen him go from swole to lean or as one commenter

put it, “From Mountain to Rock”.

“Earlier Than school, then afterwards, plus I was lifting at evening.” His intense

work ethic paid off, with the massive man shooting 64 percent and

averaging 6.7 factors for professional basketball membership Körfuknattleiksfélag FSu

in Selfoss, Iceland. At a tour of the facility, Rivera said CBP officers screen packages they deem suspicious, placing something tagged through X

ray machines. E On Day thirteen, fast partial decision of consolidation was noted 24 hours after graduation of pulse methylprednisolone

therapy. Continued approval for this indication could additionally be contingent upon verification and description of

medical benefit in confirmatory trials. Loaded with confirmed performance enhancing ingredients,

D Bal MAX is an affordable, and authorized alternative to Dianabol.

A whole of three Icelanders have won the title, two of whom, Jón Páll Sigmarsson and Magnús Ver

Magnússon, are in the WSM Corridor of Fame.

On the occasion of Björnsson’s medal, What’s On took a closer look at some “really, very” strong Icelanders

(yes, that’s a delicate reference to Seinfeld). Nevertheless, when he’s

not skull-pulping the good folks of Westeros, Björnsson has

been putting his measurement and strength to make use of in other less menacing methods.

It was only a matter of time earlier than the NFL came knocking

on the strongman’s door.

He usually consumes round 1 gram of protein per pound of physique weight

per day to help his muscle growth and restoration. Hafþór Júlíus Björnsson’s workout routine is intense and focused on building energy and energy.

He trains six days per week, with each day devoted to a selected muscle group or sort of exercise.

Björnsson’s spectacular physique is a result of his

intense workout routine and strict food plan. Despite his huge size,

Björnsson is known for his agility and velocity, which

he attributes to his coaching regimen.

After asking to skip any further questioning

in regards to the scenario, Bjornsson says the thought

of dying at a young age from overuse of anabolic bodybuilding steroids before And After is worrisome.

The Knicks have the most 20-point comebacks in a single postseason in NBA history.

Therefore, comparing Hafthor’s power with the Vikings, followers debated about their prowess through the eleventh century.

After promising his followers to hit the 970 lbs squat final week,

the strongman shared an Instagram video of attempting to pull off his goal on three April.

The Mountain’s wonderful power had fans debating about his Vikings ancestry.

This year’s World’s Strongest Man competitors is scheduled for June

in Bradenton, Florida.

This program goals to protect the spirit of strongman sports activities,

fair play, honesty, and the health of the athletes.

Nevertheless, it’s unclear how the organization tests its opponents and the frequency of those exams.

Since beginning with boxing, Hafþór has stayed involved in a range of martial

arts.

He was selected for the under-17 and under-18 sides within the mid-2000s and went pro in the season, enjoying as a middle for Division 1 staff FSU.

He was made eligible for the NBA in 2010, but he wasn’t drafted and his career ended with a

foul harm. In a latest interview with Sports Illustrated, Bjornsson shared some lofty lifting objectives.

“My finest in the bench now is 507 kilos however my objective is to blow up over 660 kilos off of my chest,” said Bjornsson.

The athlete wrapped up the detailed post by telling his fans to not be offended if he

did not appear happy to fulfill them at an upcoming strongman event.

“Please keep that in mind when you come to Europe’s Strongest Man tomorrow and get photos with me that I Am not in a nasty mood I just can’t actually smile for footage,”

he said. Many who watched the broadly circulated

video commented that Björnsson was taking it simple on McGregor, which the MMA star denied.

That does not embrace the added fruit juice that he drinks

continually to ‘get more calories’. Little by little, the Giants and powerlifters that shaped the army of Icelandic strongmen started giving way to different athletes.

Direct broadcasts stopped, and occasions like Vestfjarðavíkingurinn (‘The Viking of the Westfjords’), a

neighborhood Icelandic competitors, lost their prime time location and had been wedged between news commentaries and Sunday

morning cartoons. At fifty four years of age, Magnús Ver does not compete anymore,

however he nonetheless judges internationally and

trains world class strongmen. He lives in Reykjavík and may still bench press his own body weight with ease.

Magnús was young and vibrant, the Child in the Competition, the Fairly Boy,

and possibly even faster and more agile than his predecessor.

Later occasions have hailed him as one of the most technical strongmen in historical past, combining Jón Páll’s system of athletics and explosive velocity with a powerful static power that allowed him to outlift many skilled powerlifters.

After a two-and-a-half-year hiatus from strength

coaching, Hafþór competed in 2022 Thor’s

Powerlifting Meet in December and totaled 970

kg (2,a hundred and forty lb) raw. Then on 13 February 2023, Hafþór proceeded to officially announce his return to power

sports activities, stating he will attempt to interrupt the all-time powerlifting complete

world report at the finish of the 12 months. A week later,

he underwent a five-hour surgery in La, the place the muscle was successfully re-attached to the bone, promising a full restoration. PowerliftingDespite the truth that Hafþór

never educated specifically for powerlifting, he did two

full competitions throughout his strongman profession and another post-retirement.

c2dsk5

I have read several good stuff here. Certainly worth bookmarking for revisiting. I surprise how so much effort you place to make the sort of wonderful informative site.

Wow! Thank you! I continuously wanted to write on my blog something like that. Can I implement a part of your post to my blog?